How to Prepare for Integration: Creating a Digital Supply Chain for Automotive

July 31, 2023

About the Digital Supply Chain

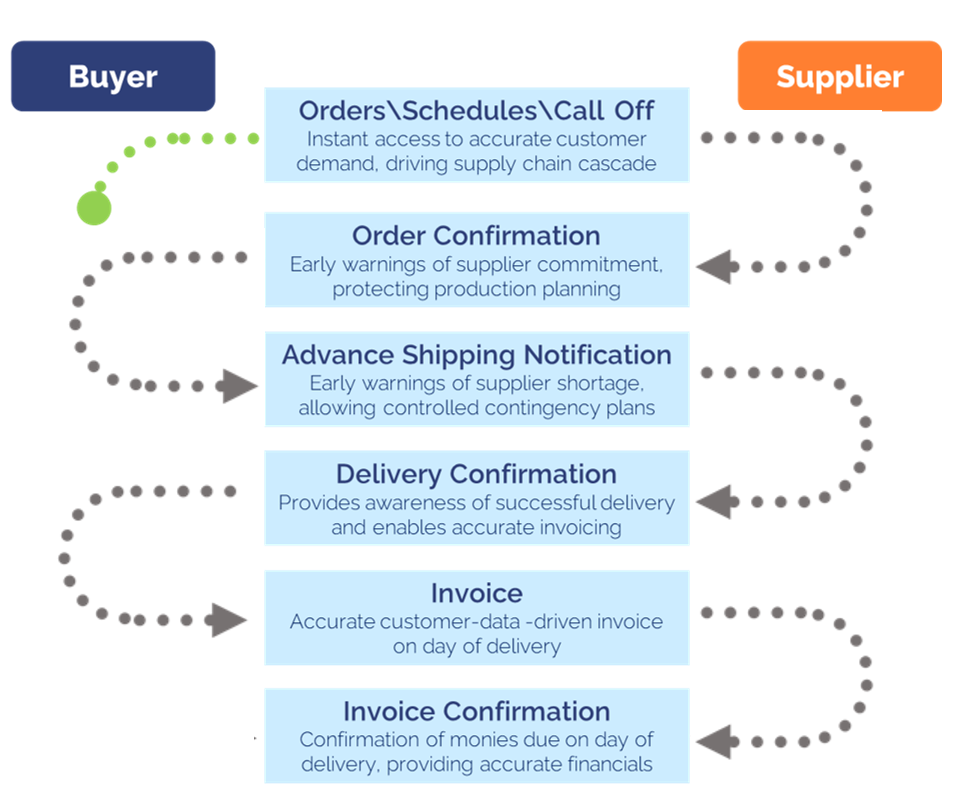

The digital supply chain is the process of communication between customers and suppliers. It’s an exchange of information, starting from the earliest forecast and going through to the actual authorized shipment and finance process.

However, other entities are involved in that communication process as well. These groups could be your transport provider, 3PLs, 4PLs, or other additional partners.

This element of the digital automotive supply chain focuses on closing the gaps where a potential stock deviation could occur, which involves tracking where the physical shipment is, acknowledgment from the transport company, confirmation of what they’ve picked up, and then what they’ve physically delivered.

Essentially, the supply chain is about achieving operational success to meet demand, including what the customer wants, when they want it, and whether you’ve fulfilled that requirement on time, the first time. The digital aspect refers to the automation of that process. A truly digital supply chain goes from Tier One to Tier Two, then all the way down to the potential raw materials.

The Modern Automotive Industry

The automotive industry is changing dramatically for a variety of reasons. There are the challenges brought on by the global pandemic and geopolitical issues compounded by the movement away from traditional internal combustion engine vehicles to electric vehicles. EV original equipment manufacturers (OEMs) consider themselves more technologically advanced than conventional OEMs and look to do things differently. They’re analyzing other supply chain management technology and how to best establish resiliency.

EV manufacturers are uniquely positioned to be trailblazers in the automotive industry. Emerging EV brands are able to build from the ground up instead of transitioning legacy systems and are developing competitive solutions that meet ROI goals. As the adoption of EVs increases, conventional manufacturers are looking to them for solutions about implementing technology to future-proof their supply chains.

Tools & Resources for Integration Success

1. Understanding Supply Chain Partners’ Capabilities

Understanding your supply chain partners’ capabilities is the most important tool for integration success. Each partner is unique and will have different standards and requirements. There are numerous partners to work with, and selecting the right ERP and EDI partner should be at the top of your list to ensure a successful integration.

Integration within a supply chain is a two-way process, and to benefit both the recipient and the sender, you must understand their capabilities, both from a process and a system perspective, creating a strategy that allows them to work the way they know instead of creating systems that dictate how they should work.

2. Quality Versus Quantity

Second, you’ve got to focus on the quality of the data. You can bring in a massive amount of data, but if that data is contradictory or dirty, you won’t get the desired result. The ability to check everything that comes in and goes out is crucial.

This can be achieved through standardized business rules that ensure the incoming orders meet the terms of the business relationship so both parties get the data in the format they need and can continue to use their processes. Understanding data changes and ensuring these changes are within the confines of a trading partner’s capability is also paramount. Comparing accurate data to the aligned business rules is necessary to determine potential deviations or disruptions to the business-as-usual process. It is critical to ensuring a smooth supply chain, cost management, and production operations.

3. People, Process, & Partnership

Finally, it’s understanding the people, processes, and partnerships involved. Whether you’re working with supply chain leaders, logistics planners, or the finance team, you need to ensure that all parties understand the processes being implemented and the perceived benefits.

Every step in the process affects the next step. If your order is incorrect, your shipment will be incorrect, and if your shipment is incorrect, how can you invoice accurately? In automotive, there is a big focus on firms and schedules, but companies need to remember how important the accuracy of data and processes is for finance.

It comes down to understanding the different people within the supply chain, the processes that are important to them, and building that digital partnership. A solid digital partnership delivers the benefits and value that all parties require.

“Gains you make in one department can quickly be lost in another area, so it’s a balanced approach from an end-to-end perspective.”

– David Eyes

When to Plan for Integration

Supply chains—especially in the automotive industry—never stop. Something is always being developed, ordered, shipped, or delivered. You can’t just switch your system off to initiate a supply chain integration, so when planning for integration, you must investigate why you need it and when. Below are some of the key reasons why organizations would consider taking on the task of integration:

- Switching ERPs

- Replacing outdated systems

- Bringing in new trading partners and business

- Reducing fulfillment issues and increasing production run rates

- An increased need for data visibility and improved performance

- Adapting from Just-In-Time or Just-In-Sequence

- Reducing costs associated with Stock-on-Hand

The events of the last few years have highlighted the weaknesses of on-premise ERP systems and a need for supply chain visibility. While processes like Just-In-Time and Just-In-Sequence have been effective in the past, they are very susceptible to disruptions from outside sources, and many organizations are looking to move to more modern, cloud-based solutions.

It is best not to leave it until you have gone on mass production or as a business-as-usual process. If you have the opportunity to make these changes as part of a new business process or when making significant business changes, that’s the optimal time to look at implementing an ERP integration.

This shift to digital ERP integration in automotive can be more difficult as many key players have used manual processes or legacy systems for years. Initiating a modern, cloud-based integration can be intimidating, so it’s important that everyone is on board and become partners of the change, not problems of the change.

Building a Digital Supply Chain for Automotive with TrueCommerce

TrueCommerce is taking out the complexity of the automotive integration with our automotive supply chain management solutions.

TrueAuto is an iPaaS B2B solution designed to digitize an automotive manufacturer, from the largest OEM to the smallest Tier supplier. Working together with existing technologies and systems, TrueAuto provides the necessary functionality to proactively manage the automotive supply chain and achieve compliance in accordance with industry best practices. We simplify mapping, replacement logic, and reconciliation, creating a simple and efficient process.

When it comes to clean data, ensures quick access to impactful data and acts as a filter between the end user’s systems and their customers. Additionally, TrueAuto adheres to compliance standards within the industry, including MMOG/LE, and is Honda approved. All of this is conducted within the cloud utilizing our fully managed service. Contact us today to learn more!

About the Author

David Eyes has long been an influential figure in supply chain management and digitalization markets. With more than 25 years of expertise in supply chain business development, David has helped hundreds of businesses leverage integration and automation for greater success. In addition to his position at TrueCommerce, he also serves on the advisory boards for the Alabama Automotive Manufacturers Association (AAMA) and Georgia Automotive Manufacturers Association (GAMA), acting as Chairman of the GAMA Supply Chain Committee. When he isn’t helping business owners, David uses his knowledge and passion to support supply chain education in younger generations, regularly visiting and speaking at schools, colleges and universities about opportunities in the field.

Share this post:

Categories

Stay ahead of the competition

Get expert supply chain insights delivered directly to your inbox weekly.