SMD LEDs: what they are and the existing types

SMD LED modules are now widely used in the manufacture of LED luminaires and LED strips for various applications in different sectors. This technology is used wherever high efficiency and precise control of light distribution is required.

SMD LEDs are characterised by high durability, low power consumption and high standards of reliability and safety. But what are SMD LEDs? Let's find out together.

In this in-depth look at SMD LEDs we will cover the following topics:

- SMD LEDs and SMD LED chips: what they are and what they mean

- Soldering SMD LEDs: how to do it?

- Types of SMD LEDs: all those you need to know

- SMD LED dimensions

- COB or SMD LEDs - what are the differences?

- Micro SMD LEDs - what they are

- SMD RGB LEDs - what they are

- LED SMD: the colours available

- SMD LED diodes and polarity

- The SLIM range of SMD LEDs

Let’s shed light on SLIM light signaling solutions

|

Do you want to stay up to date with industry news? Click on the button below and subscribe to the SLIM newsletter!

SMD LEDs and SMD LED chips: what they are and what they mean

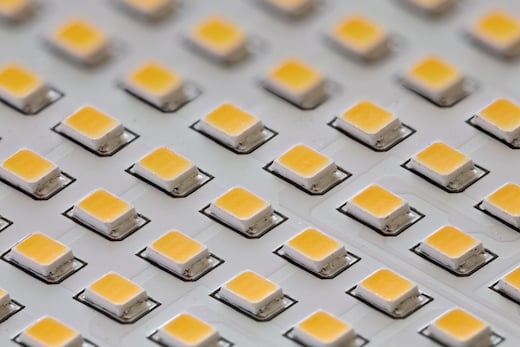

SMD LEDs stand for Surface Mount Device and Light Emitting Diode. The combination of these acronyms indicates electronic components made up of LED modules that are mounted directly on one side of the printed circuit board using surface mount technology, known as SMT.

SMD LEDs are characterised by a parallelepiped shape, called a chip, which contains the emitting surface inside. The diodes that power the device are located on the sides.

Soldering SMD LEDs: how to do it?

SMD LED chips are self-contained LED devices that are mounted on the surface of the printed circuit board (PCB) by soldering, using SMT technology. This practice allows the SMD LEDs to be soldered onto both sides of the circuit board, without cutting or drilling into the board.

The advantages of using this type of component assembly are:

- the possibility of using reduced components and making more compact electronic boards;

- a reduction in the production of scrap resulting from the circuit drilling operation;

- a consequent reduction in working time, as a series of automated machines are used, including the Pick&Place machine.

Types of SMD LEDs: all those you need to know

There are different types of SMD LEDs, and each variant is identified by a series of numbers that define its size and associated brightness level. The LED identification number corresponds to the size of the chip itself, expressed in millimetres.

As for the main types of SMD LEDs, the most common on the market are the 3528. This was one of the first LEDs to appear on the market and is characterised by a power of between 6 and 8 lumens, a consumption of 0.20W and a very low light output.

The SMD 5050 LEDs provide an output of between 16 and 22 lumens. They are among the first chips to generate higher power and are therefore suitable for general lighting needs.

The recently developed SMD 5630 and 5730 LEDs provide good brightness at low power consumption and are therefore very popular. These SMD LEDs are suitable for use where high lumens are required.

Finally, SMD 2835 and 3014 LEDs are identified as having the longest life and best performance, due to the presence of a heat sink inside them that prevents the source from overheating. This type is usually used on LED strips for both lighting and purely decorative purposes.

SMD LED dimension

SMD LED chips are characterised by a rectangular shape that varies in length and width depending on the model. Generally, however, regardless of size, SMD LEDs do not exceed 5.7 millimetres in length and 5 millimetres in width.

The size of the SMD LED is what has the greatest influence on the brightness and power consumption of the device. The larger the device, the higher the brightness level. These characteristics are easy to understand thanks to the numerical abbreviation that identifies the different types of LED.

COB o SMD LEDs - what are the differences?

The term LED is often found in association with other acronyms, as seen with SMD LEDs. The term COB LED refers to chip-on-board LED technology. This technology was introduced in 2011 and enabled the development of high-power diodes with a small light-emitting surface area.

Why should you choose COB or SMD LEDs? The introduction of COB LEDs has brought with it some significant advantages. First of all, the possibility of miniaturising the luminaires and the light sources inside them. COB technology facilitates the installation of individual plates in close proximity. This allows precise control of the distribution of the light beam thanks to the absence of space between one LED module and another. However, one application limitation of this technology is the power rating of the luminaire (possibly less than 50/70W) on which it is to be installed. SMD LEDs are to be preferred over COB technology precisely because they are more reliable and perform better in high power applications.

Micro LED SMD - what are they

Today's market demands ever smaller, yet more efficient LEDs. The search for even better-performing SMD LED chips has led to the development of devices capable of achieving truly brilliant lumen/Watt ratios, thus enabling the development of ever-smaller luminaires. This has led to the development of SMD micro-LEDs, highly efficient miniaturised technologies for small circuits.

One example is the micro-LED circuit developed by Luxelt. The Italian company, which specialises in the design and production of electronic and lighting systems, has developed cutting-edge technology that we have used in our new series of micro-LED spotlights.

Would you like to receive more information about micro-LED spotlights? Click on the button below and feel free to contact us!

SMD RGB LEDs - what they are

SMD RGB LED technology allows the colour of light to be changed by using three diodes: red, blue and green. In order to vary the colour of the light, these diodes are mixed according to precise intensities.

In backlighting projects, it is common to use an RGB SMD LED source to give the light profile an aesthetic and design component and at the same time a functional aspect. Each colour can be associated with a specific application status to communicate a precise function to the end-user.

SMD LEDs: the colours available

SMD RGB LEDs offer a wide variety of colours in different combinations: blue, red, yellow and many others. The RGBW LED also has a white SMD LED variant, which stands for Red Green Blue and White. In the case of white SMD LEDs, a different shade of white can be seen depending on the specific source. The colour temperature of white, which can be warm, cool or neutral, depends on a number of factors, including the bin colour of a specific LED manufacturer.

SMD LED diodes and polarity

SMD LED polarity identifies the specific polarity of each LED module. The SMD LED diodes must respect the polarity and the operating voltage in order for the device to work correctly.

LEDs are formed by the presence of two pins, anode (+) and cathode (-), which mark a different polarity. On some types of LED, symbols can be found on the housings that specify the polarity of the chip.

The SLIM range of SMD LEDs

SLIM works with third-party companies to supply high-quality SMD LEDs. Among these companies is Luxelt, with the design and development of PCBs with high luminous efficiency and low power consumption SMD LEDs. These latest-generation SMD LEDs are used to develop customised lighting solutions for a variety of application areas, with particularly interesting projects in the HO.RE.CA, professional coffee machine and food equipment sectors.

Would you like to discover the collaborations that have led to the design and development of customised solutions with LED technology? Click on the button below and download the free document on SLIM's success stories!