Our background, education, work experience and exposure to technologies often results in us being trained to a way of thinking, so thoroughly, that we’re sometimes unable to think differently to give us the cutting edge we need. It’s that ‘thinking outside the box’ phrase we’ve come to hear and loath.

Breaking out of that proverbial box requires courage, innovation and investment. In the engine design world, it’s a paradigm shift in thinking which leads the exploring engineer into engine combustion strategies which are possible with the use of a variable valve train system, in particular, our Lotus AVT system.

But, it’s not just about seeing data from a different angle. It’s about access to new and previously unavailable data, this is what makes the difference. It’s a dream world of a valve control system operating in real time and adjusting individual valves according to the demands of the ECU.

A world where the physical link between the crankshaft and the valves is completely decoupled, thus enabling the opening of valves at every stroke to run as a two-stroke or as a conventional four-stroke operation, and event to venture into six-stroke and eight-stroke combustion.

Multiple exhaust valve events become a reality and a whole spectrum of new combustion strategies becomes possible. With over 30 Lotus AVT systems now sold worldwide, it’s important that we take note of global market trends and client feedback as we forge ahead into a strong legislatively‑driven world of emissions control and fuel economy.

The research departments of major OEMs, research institutes and universities around the world benefit from the ability to control each valve independently with the potential for cycle to cycle variation and high operating speeds up to 8,000 revolutions per minute using the latest AVT system.

So, what is AVT?

The Lotus Active Valve Train (AVT) is an electro-hydraulic product which is used for engine research and incorporates the independent and flexible control of engine valves on adapted client engines – meaning any number of engine valves can be operated at any one time using any available lift profile.

It is a sophisticated research tool, for use in engine test cells and incorporates many engineering disciplines: mechanical and hydraulic, electrical and electronic, software and control. It is used in a variety of investigative spheres: performance and combustion strategies, engine and fuel design, emissions control and efficiency.

Instead of the conventional camshaft and return springs which control engine valve movement in a fixed relationship, AVT gives true fully flexible and variable engine valve movement without any need for a Camshaft. It is camless valve operation with no return springs.

The opening and closing of engine valves is controlled electronically, and operated hydraulically, which gives full control of individual engine valve lift profiles for client engines. It provides a tool for faster in-depth research into advanced combustion strategies, performance and fuel economy and is the enabler for advanced low temperature combustion techniques such as HCCI/CAI.

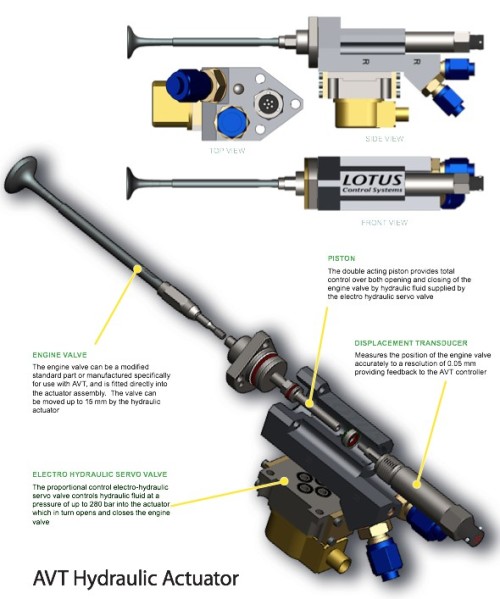

A hydraulic power pack supplies pressurised hydraulic fluid to the electro-hydraulic servo valves which control the flow of hydraulic fluid proportionally to either the top or bottom of each double-acting actuator piston which connects to an engine valve.

This enables control of the velocity, timing and lift displacement of the engine valves for each individual crankshaft degree of rotation. It is possible to vary the opening and closing points of fully definable profiles individually in one‑degree increments while lift is adjustable to any valid figure between 0.01 mm and the maximum travel of the actuator (around 15 or 16 mm). The system employs a closed-loop control algorithm with displacement feedback to detect and correct the actual measured displacement towards achieving the desired displacement (it’s a phase-advanced PID control algorithm).

Further optimisation of the profile is achieved by adjusting the algorithm tuning parameters manually. The effects of this manual tuning can be observed immediately and gives a visual check on the quality of fit between the demanded and achieved profiles. With a sampling rate of 40 kHz, the system status is monitored to identify potential malfunctions triggered by alarms, hydraulic pressure loss or valve to piston clash scenarios, etc.

The Lotus designed multi-layer IOI (Input-Output Interface) PCB and electronics make for convenient connection to client facilities and safety interlocks, thus ensuring compatibility and the protection of personnel and equipment in what is a high-stressed control environment. The processing power of the PC is harnessed by the Lotus IOI plug-in board thus enabling us to concentrate on the control process while leaving processing speed and power to the PC manufacturer.

The PC-based user interface will be familiar to modern software users. The Microsoft interface provides an ease of use which is clear, configurable and intuitive. The monitoring of engine speed and system pressure takes place alongside profile switching and control of valve actuation and parameter tuning, to name but a few.

The ability to switch profiles is one of the significant advantages of using the AVT system. During an engine test session, it is possible to select any valve profile from a library of 128 lift profiles for each engine valve. Each of the profiles can also be phase advanced or retarded by 128 degrees. If required, whilst the engine is running, a lift profile can be switched in real time. The profile itself can contain as many lift events as are physically possible to implement. For example an engine can be configured to switch between two and four stroke combustion.

Recognising that this cannot be performed manually for any length of time, the instructions for such operations can be linked to the client ECU via the CAN bus. This allows the programmatic introduction of a different profile based on the decision-making assigned to the ECU software and could relate to any optimal engine condition during the test, for example, exhaust emissions or engine performance.

Even though there is a limitation to using only one profile library (of 128 profiles) at a time, the discerning engineer will have any number of libraries available at their disposal so that these can be used as required. The build-up of profile libraries becomes the knowledge base of the engineer and libraries of many thousands of lift profiles can be specified for use in their engine test programs.

Even though there is a limitation to using only one profile library (of 128 profiles) at a time, the discerning engineer will have any number of libraries available at their disposal so that these can be used as required. The build-up of profile libraries becomes the knowledge base of the engineer and libraries of many thousands of lift profiles can be specified for use in their engine test programs.

In addition to supplying the AVT system, we offer installation, commissioning, training and support. This is vital because clients who have made significant investments in the technology like to know that they are supported. Customer relationships have always been considered to be crucial to our work and this has proved itself over many years.

The steps from sales to project management to technical knowledge is an ongoing relationship where first names, open dialogue and confidentiality have become part and parcel of our delivery. The results, especially in recent years, have led to clients having multiple AVT systems along with our ongoing support.

Lotus AVT in its current configuration is not a production system which is ready for OEM use in vehicles. AVT sits firmly in the test cells of the research community and this is what is often misunderstood.

We’re not trying to compete with Fiat’s MultiAir, Honda’s VTEC or BMW’s Valvetronic production systems. These are solutions for road vehicles and are optimised in operation so that they don’t require the total flexibility offered by a fully variable system used for research. These are different arenas and both are very much relevant to production and to research engineers.

Where do we go from here?It’s a question asked often.

On at least 30 occasions to date, the Lotus AVT system was chosen to assist engineers with their combustion research work. In many cases we believe wins against other competitor systems were because we offer significant advantage and benefits in research which cannot be easily matched.

At the time of writing (March 2014), we’re communicating with ten different (mainly) existing clients across the globe including seven major OEMs: three in the USA, three in mainland Europe and one in Japan. Discussions for assistance range from spares and support contacts in the USA and the Middle East to feasibility studies and new systems in Europe and the Far East. Interest and potential applications are high and encouraging, as engineers strive to achieve more efficient combustion systems.

We recognise that AVT needs to move beyond single cylinder application into the more demanding multi-cylinder application. We recognise too that universities are an important investment into the future and they would welcome a more targeted product.

Writer: Steve Louis - Control Systems, Lotus Engineering

Discussion

Comments are closed.